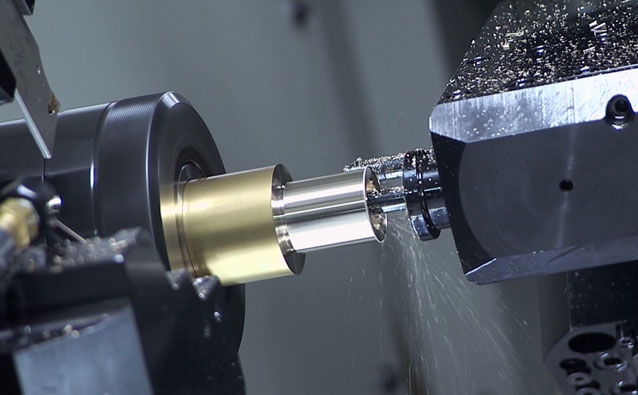

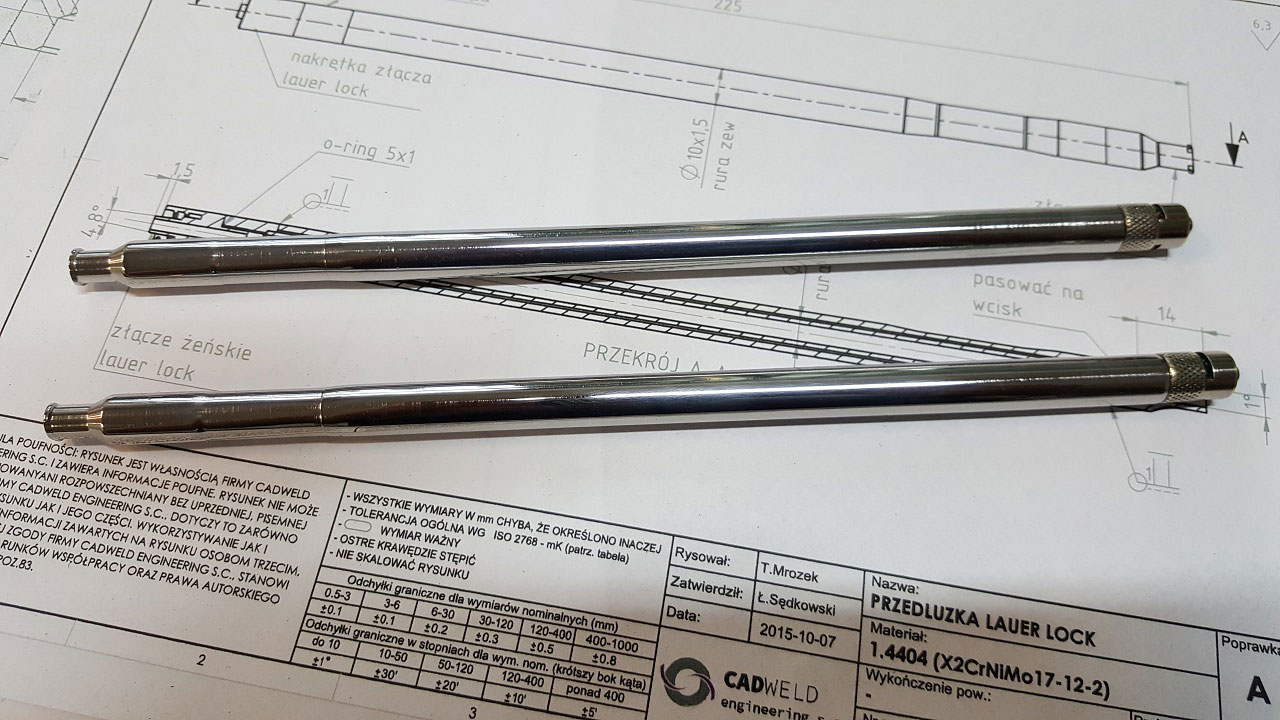

CNC turning

2 CNC lathe CKT 360×750

Max turning diameter: 360mm

Max turning lenght: 750mm

Bar capacity: 38mm

Spindle max rating: 3,7kW

Control: Sinumerik 808d

2 CNC lathe CKT 360×750

Max turning diameter: 360mm

Max turning lenght: 750mm

Bar capacity: 38mm

Spindle max rating: 3,7kW

Control: Sinumerik 808d

Vertical machining centre INTERCNC VMC400

Max table load: 150kg

CNC axis: 3

Travels: X/Y/Z 400x300x500

Spindle max rating: 3,7kW

Tools capacity: 12

Control: GSK 218MHc – connected with CAM system

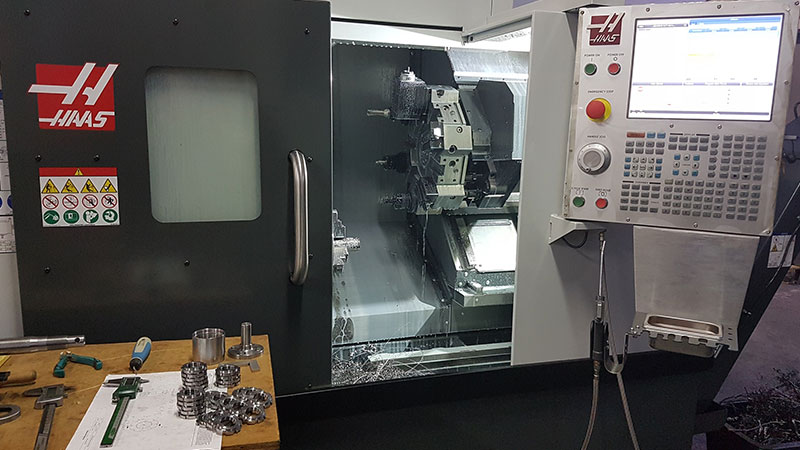

HAAS ST15-Y

Max turning diameter: 305mm

Max turning lenght: 406mm

Bar capacity: 64mm

CNC axis: 4

Spindle max rating: 14,9kW

Control: HAAS

EDM max height: 350mm

Travels: 300×360

Table size: 600×403

Angular cutting – 6 degree

Accuracy: 0,01mm

Efficiency: 80-120mm^2/min

Control: AutoCut

3 conventional machines:

2 lathes: turning diameter up to 360mm and length 750mm

Power: 1.5kw

38mm spindle passage

1.5kW milling and drilling machine for pre-treatment and small parts

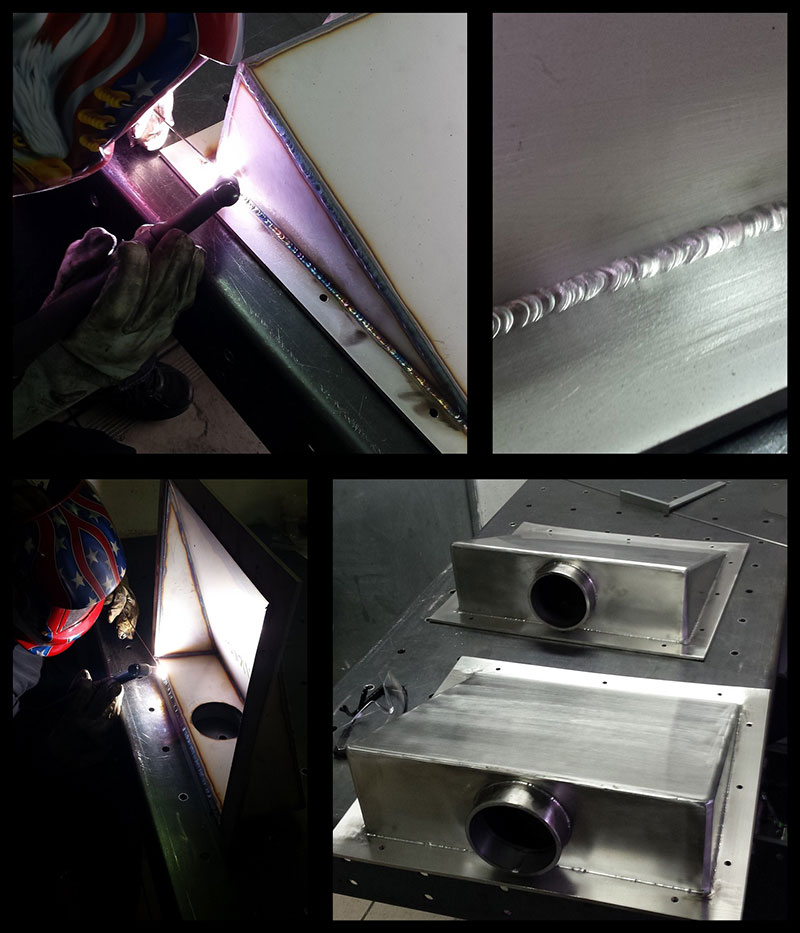

Welding machine: ESAB CADDY TIG 2200i

Maximum current: 220A

We specialize mainly in welding stainless and acid-resistant steels. We focus on precise, small dimensions parts and parts requiring jigs.

We have 2 stations equipped with MAGNUM 280A industrial welders with a maximum welding current of 280A.

We mainly make platforms, transitions, stairs and frames for the needs of machine construction and production using the MAG method. We make constructions up to 3m in length and weighing up to 100kg.

We make details according to customer specifications or according to the provided pattern. We make prototype elements and undertake serial production. We cut details up to 20mm thick in black steel and 15mm in stainless steel.

We bend or press cut details according to our technical capabilities.

We have 2 band saws for cutting and material preparation.

We drill and thread holes. We have full capabilities in grinding, chamfering or deburring

We have a working post for glass slides after processing.

We carry out assembly of machines and devices constructed by us as well as according to the customer’s design. We provide care for machines and warranty or post-warranty service.

We help in starting CNC machines and preparing them for work.

We undertake the regeneration of machine parts, replacement of components and making new components for repair based on the documentation provided or worn parts.

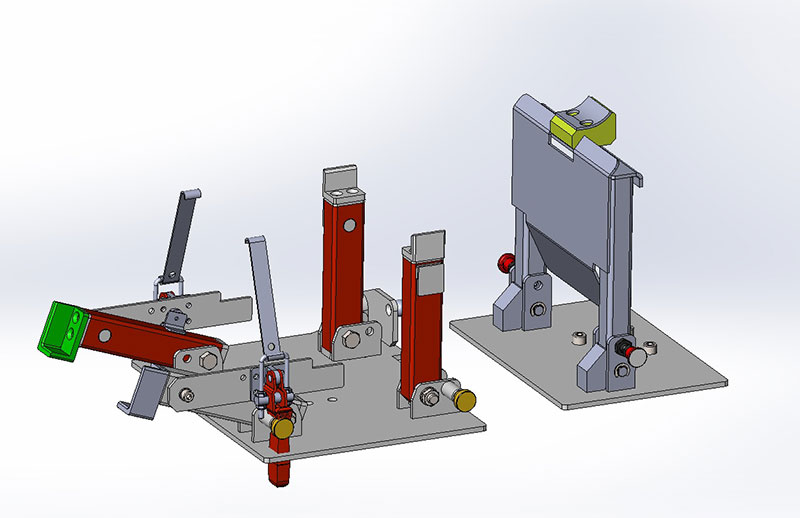

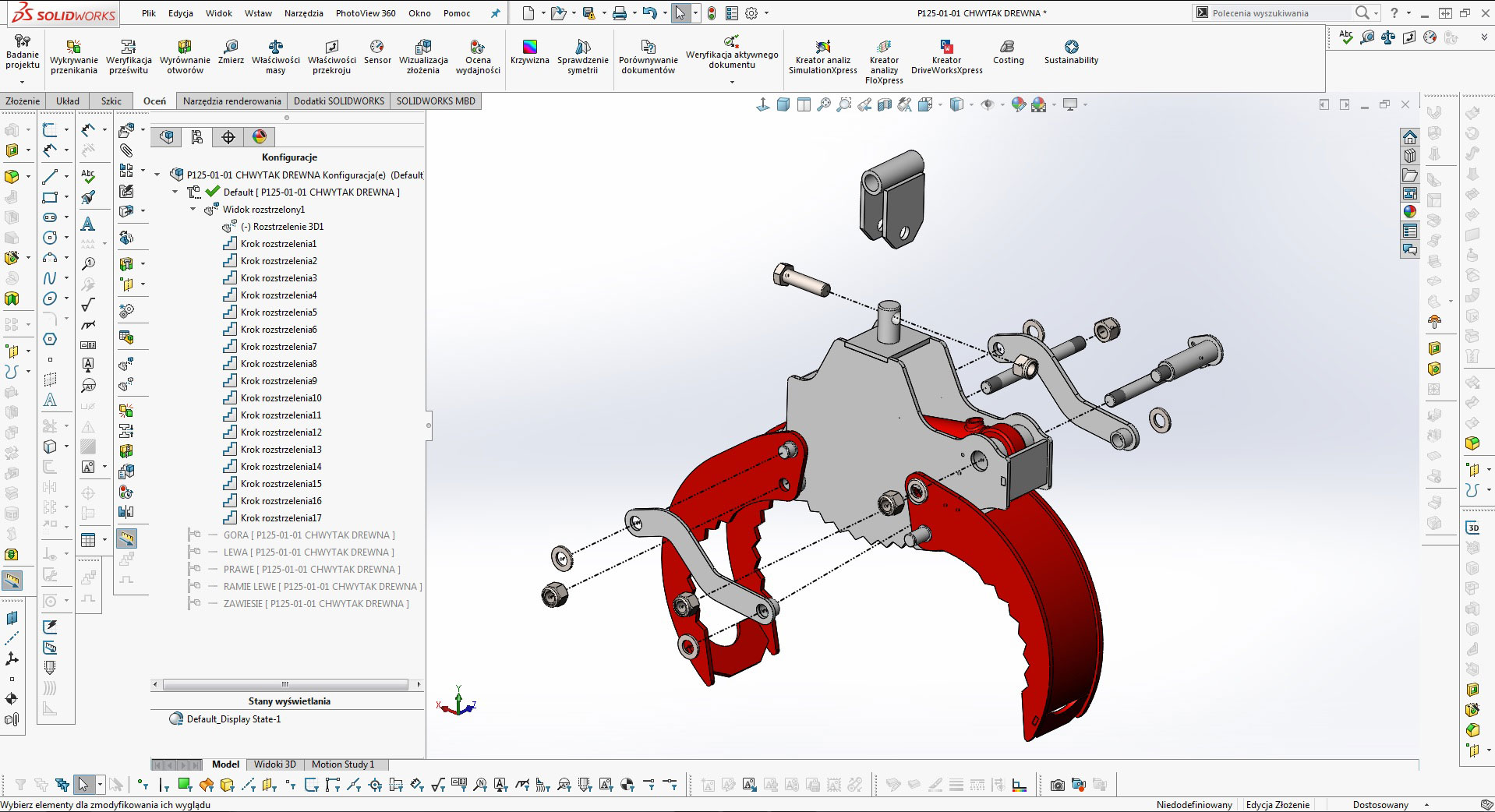

We have an advanced CAD-3D SolidWorks engineering design system.

We make full technical documentation for implemented projects, we process paper documentation into electronic. At the client’s request, we prepare material lists or auxiliary drawings.

Our CAD system is integrated with an advanced CAM system for computer-aided programming of CNC machines. It gives you the ability to quickly and effectively program the machine for machining even a very demanding detail.

We have the ability to program machine tools with Sinumerik, GSK218, HAAS control

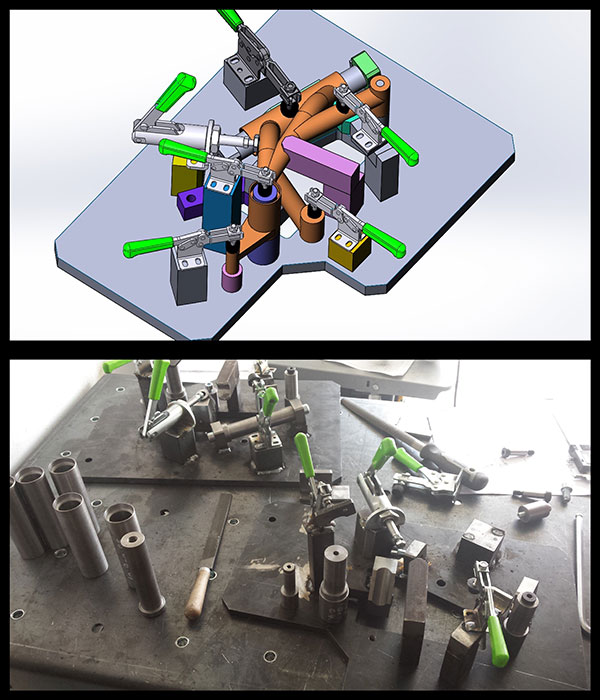

We make designs and prototypes of tools based on customer patterns as well as solely on the basis of his requirements and expectations.

We design and manufacture tools for the automotive industry, household appliances and the cosmetics industry

In connection with our welding services, we construct and perform welding equipment for both small and uncomplicated elements to very complex spatial constructions, e.g. motorcycle frames and scooters

We have software integrated with the CAD-Photo 360 system as well as separate KeyShot software, which allows us to develop a fully realistic product visualization before its actual implementation. We make visualizations for engineering and marketing purposes, e.g. checking product interest.

We have extensive experience in the design and construction of control and assembly devices for the needs of production, cosmetics and medical laboratories. We implement products for both small needs and mass production.